History of the Farley Boat Works

The Farley Boat Builders Arrive

The brothers Barney and Fred Farley arrived on the Texas coast in 1910. Barney ended up in Port Aransas, while Fred lived just north in Rockport.

Barney aspired to be a tarpon guide. While he was learning those skills, he determined that a man who could provide the guides with reliable and affordable power fishing boats could do well in Port Aransas. He shared that thought with Fred, who just happened to be a master wood worker.

Seeing a good business opportunity at hand, Fred Farley moved wife Mabel and his sons to Port Aransas in 1914 and established the Farley and Son Boat Works. The son was Jim, but eventually his brothers, Don and Fred Jr., became involved in the family business, too. The boat builders got right to work and the first Farley boat produced expressly for Port Aransas tarpon fishing was launched in 1915.

The arrival of Charles Fredrick “Fred” Farley ushered in six decades of excellence in both the building of boats and the conducting of business affairs. Indeed, the Farley boat building story is an important chapter in the maritime history of Port Aransas, Texas. Barney Farley did become a fishing guide, and then went on to be a leader and prominent businessman in the town’s fast growing sport fishing industry.

First Farley Tarpon Boats

The first Farley tarpon boats are well illustrated by the two bottom boats in this photograph of guide boats moored at a Port Aransas pier in the 1930s.

The boats accommodated two fishermen seated in stern facing fighting chairs — note the chair with arms.

These Farley boats were open cockpit craft having no significant vertical structures, a feature letting the fishermen and guide fish, fight and land tarpon without any obstructions in the way.

This line of Farley fishing boats was 16 to 28 feet in length.

Speedboat, Circa 1928

This action image shows that the ability of the Farleys as boat builders was not confined to fishing craft alone. The Farleys built this speedboat circa 1928 for Gail Borden Munsill of the Borden dairy empire.

Port Aransas was Mr. Munsill’s place for fishing, waterfowl hunting and going 60 miles an hour in his super fast Farley boat. In exchange for the enjoyment Port Aransas gave him, Mr. Munsill was a generous underwriter of progressive features for the town, such as the first telephone exchange.

The Farley Boat Line Evolves

The initial line of Farley boats built for the tarpon guides were open cockpit craft without windscreens. That simplicity was countered by the paying customers getting wet from blowing sea spray, and so windscreens were added to the next line of Farleys. With or without that feature, the open cockpit boats were quite successful and provided many years of service. In fact, the stern section of an open Farley boat is still seeing duty as a static display in the Port Aransas Museum.

This type of fishing boat is associated with engaging entries in the field diary of guide Ted Mathews. While fighting desperately for their freedom, tarpon were known to leap into these open boats. The crashing down of a thrashing 5-foot, 70-pound fish would change a fun day into one of real chaos.

Photo: An open cockpit Farley boat heads to the dock towing one, possibly two, tarpon.

Continued Evolution of the Farley Boat

Addition of a Cabin

The addition of a cabin — or house, in boat building jargon — provided dry and secure storage for rods, reels and duck hunting shotguns. Cabined Farleys were not hunting boats, per se. They towed skiffs to the waterfowl flats where the hunters transferred to the little boats to reach the duck blinds.

Corporate Boat

This Farley boat, which shows signs of advancing design, was a corporate boat owned by the Humble Oil Company and was used to take VIPs fishing. The ship in the background is the aircraft carrier USS Lexington.

Final Line of Farley Boats

As offshore interest picked up when the tarpon fishing began coming to an end in the 1950s, the final line was built to cruise offshore, in pursuit of such fish as wahoo and ling. The offshore features in this boat are the sharply angled bow stem (clipper bow) and the flaring sides (dark colored section).

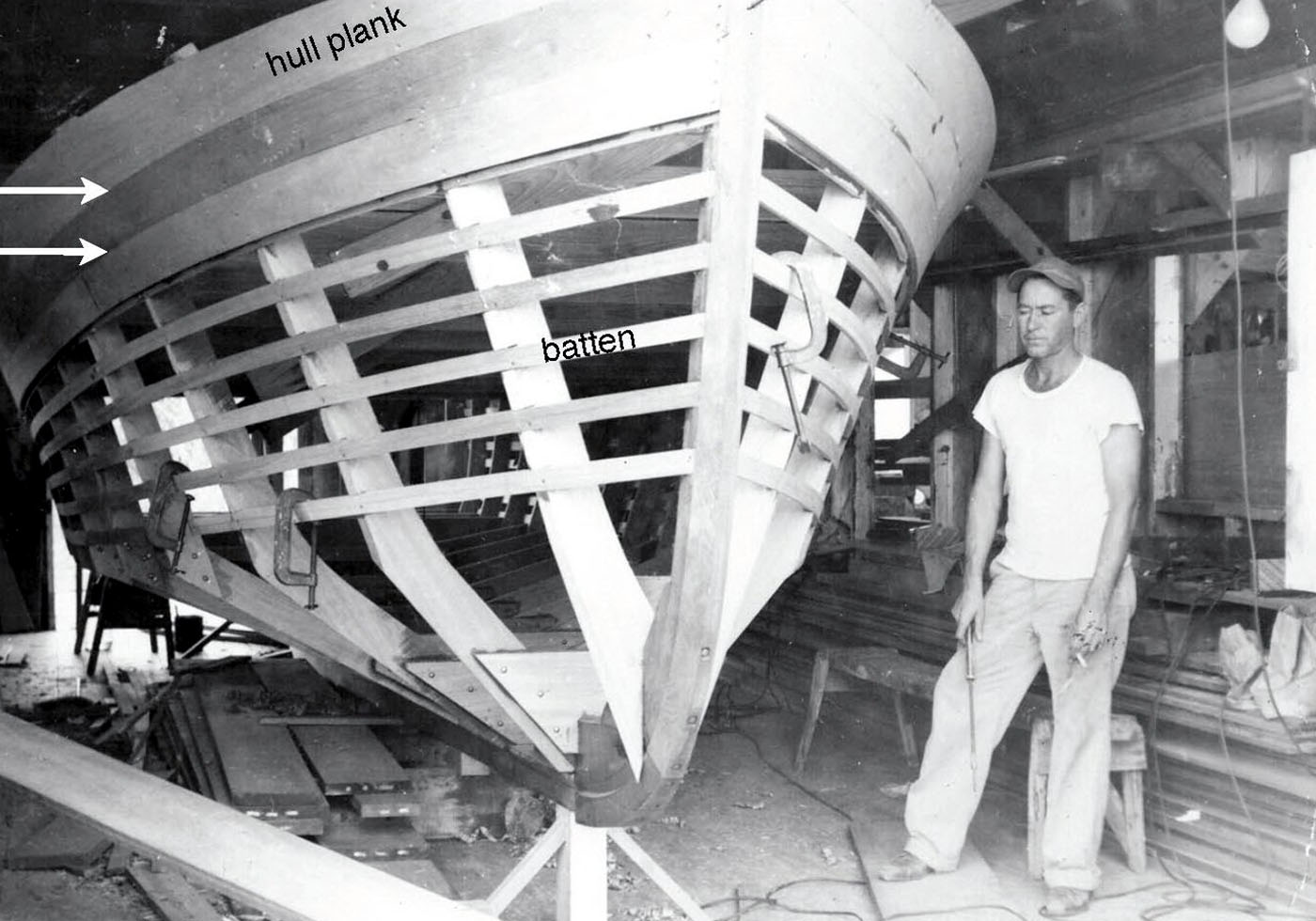

Batten Seam Boats

Battens are the long horizontal strips of wood, and a seam is where the 5/8” hull planks meet one another. Batten seam construction means that behind each seam there is a batten, a building technique that enhances the strength and waterproof quality of a boat’s hull.

Prior to World War II, the hull planks of Farley boats were cypress wood, but so much cypress was used in making wartime products that it became scarce and the Farleys had to convert to mahogany.

World War II also determined how Farley boats were powered. Before the war, power plants were everyday car and light truck engines often provided by the boat customers themselves. The standard stick shift transmissions of these engines were retained and proved an asset to tarpon fishermen: tarpon are fished by trolling bait (mullet) at various speeds, and standard transmissions produced the desired range of trolling speeds.

After the war, the great marketplace of surplus goods meant that costly marine engines could be acquired at surplus prices, and the use of automobile engines in Farley boats fell off dramatically.

Jim Farley and a partially completed boat comprise the most informative, if not most famous, of Farley boat building images. The white arrows in the photograph mark two plank seams.

The Farley Shops

The Farley Boat Works had four locations in Port Aransas.

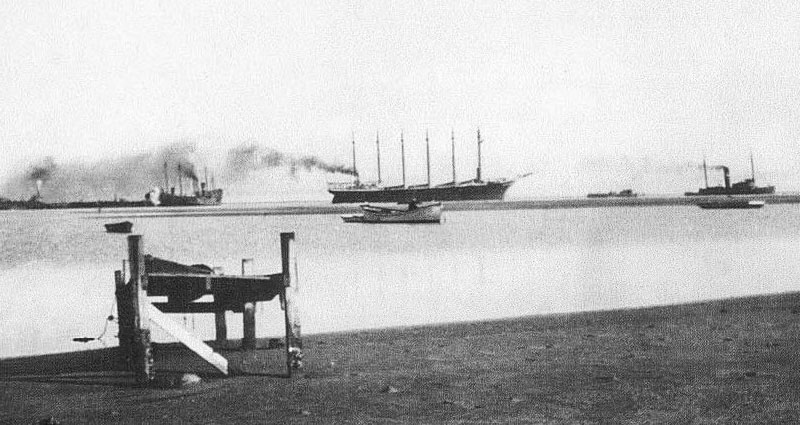

1st Location - Waterfront

The first Farley location was on the waterfront. There is no image of the waterfront operation; however, this photograph shows the waterfront at about the time the first Farley boat was launched in 1915. Having the Boat Works at water’s edge certainly expedited the launching process. In the background (to the north) are a large schooner and small freighter. The vessels are coal burners.

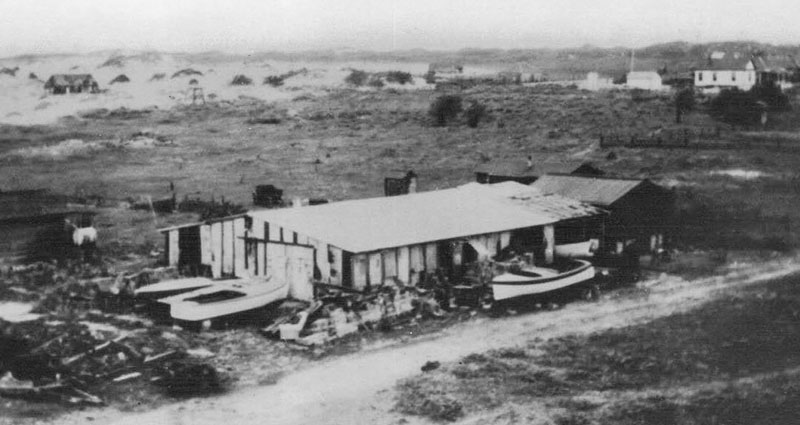

2nd Location - East of the Tarpon Inn

The 1919 hurricane devastated the Port Aransas waterfront, no doubt motivating the Farleys to move their operation inland. As shown in the photograph, the second Farley Boat Works structure had shellcrete siding, a coastal building material that uses cement made from burnt oyster shells. This Farley Boat Works was just east of the Tarpon Inn.

3rd Location – White Avenue

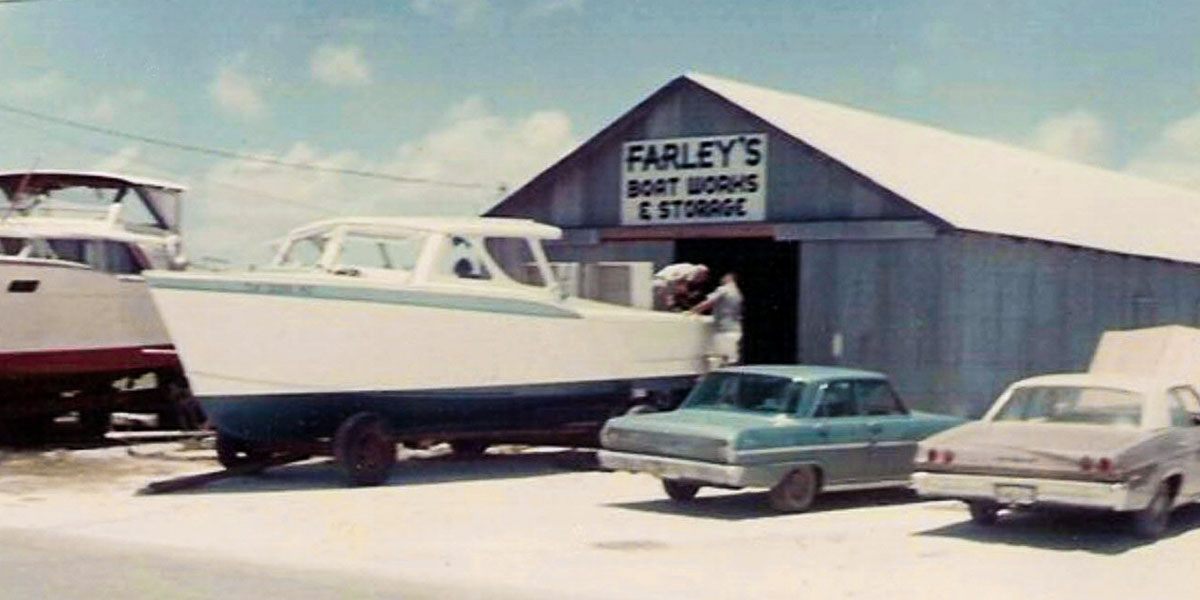

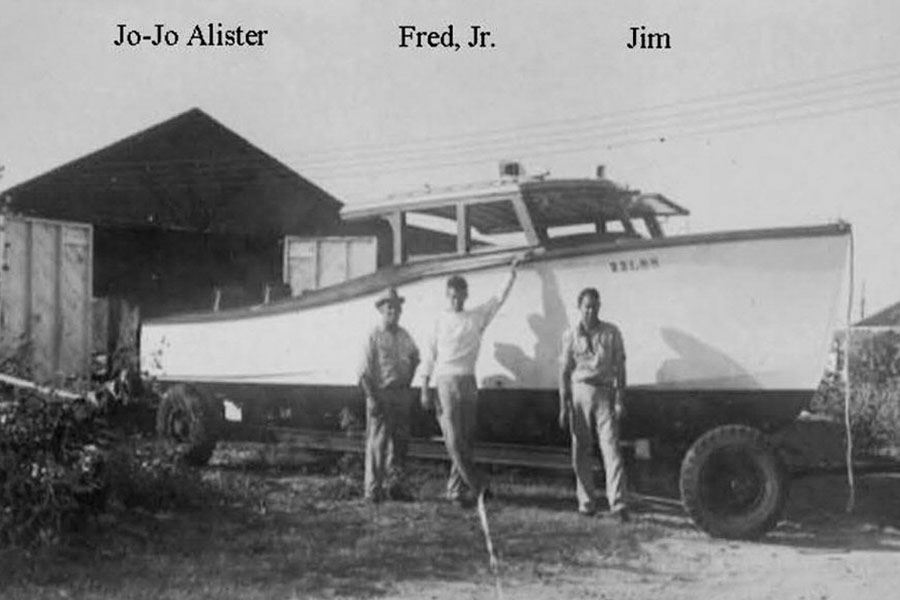

White Avenue was the third location of the Farley Boat Works. The two operations shown here were each at the White Ave. location at different times. Jo-Jo Alister, Jim Farley and Fred Farley, Jr. are seen in front of the boat works in one of the photos. Jim and Fred, Jr. are Fred Farley’s sons.

Final Location – 716 West Avenue C

True to their nautical philosophy, the Farleys continued building wood boats even as fiberglass was dominating the personal watercraft industry. The Farleys joked that if fiberglass boats were meant to be, nature would have provided fiberglass trees.

The Farley Boat Works closed in 1973, marking six decades of history making maritime operations.

After Farley Boat Works closed, the structure housed Steve’s Boat Works, owned by Steve Janovsky, followed by Camric Boats, owned by Cameron and Rick Pratt.

The last Farley Boat Works at 716 West Avenue C has been restored and is now a living museum with a functional boat building shop.